Installation instructions

When installing and operating a variable area flowmeter,

some points must be taken into account for trouble-free operation.

Always observe the manufacturer's installation and operating instructions!

Installation position

Variable area flow meters in standard design must be installed vertically, with the flow from bottom to top.

This is the only way the float can rise freely and correctly.

For horizontal installation, special devices must be used in which a spring serves as a restoring force.

Vent pipes

Air bubbles (in the case of liquids) or condensate (in the case of gases) can falsify the measurement result. The pipes should be vented and flushed before commissioning.

Calming section

Straight pipe sections without fittings, bends or valves should be provided upstream and downstream of the measuring device (at least 5-10 pipe diameters). This minimizes flow turbulence.

Clean medium

Foreign particles or dirt can block the float. If necessary, install a filter upstream of the measuring device.

Pressure and temperature limits

The permissible operating conditions of the device (pressure, temperature, medium) must be checked and adhered to.

Vibrations

Strong vibrations of the system can make reading difficult and affect the measuring accuracy.

Problem prevention

Water hammer

Water hammer can occur in pipelines filled with liquid.

It is caused by the abrupt opening or closing of a ball valve, solenoid valve

or other fast-closing shut-off valve

Due to the inertia of the liquid in the pipeline and the abrupt braking or acceleration of the

liquid column, a considerable increase in the operating pressure can occur in the millisecond

range.

A gas inclusion in the liquid that is compressed and expands elsewhere in the pipeline can also

trigger a water hammer.

This can result in the destruction of the measuring tube (breakage or deformation), damage to the

float stop or even the mounting of the measuring device. This can be remedied by using slow-closing

shut-off devices (e.g. valves) or pressure surge reducers installed in the system.

Distance measuring instruments

In the case of units equipped with a reed contact or a magnet-guided display unit, or intended for

such retrofitting, a magnet is always installed in the float.

When mounting, a minimum distance between several units must be provided, as otherwise the magnetic

fields may influence each other, resulting in incorrect measurements. A vertical offset of the units may

also be sufficient.

Ferromagnetic plant components on which the meter is mounted can also influence the measurement.

The minimum distance is determined by the manufacturer.

Pulsation of the float

Due to the system, e.g. pulsating flow generated by peristaltic pumps, pulsation of the float may

occur. This makes it difficult to read a measured value on the scale of the flow meter.

This can be remedied by a flow rectifier to generate a uniform flow or a flow meter with a different

measuring principle.

In addition to these system-related pulsations, incorrectly dimensioned variable area flowmeters

can also cause so-called compression pulsation.

This mainly only occurs when measuring gases.

It occurs when the operating pressure is not sufficient to overcome the back pressure generated by the

float and thus the float can be lifted.

The gas is compressed in front of the float until there is sufficient pressure to then lift the

float explosively.

Due to the resulting larger annular gap between the measuring tube and the float, the gas expands

again and the float falls back into its initial position.

The process is repeated and the float pulsates.

This effect often occurs during the start-up of a system when there is not yet sufficient operating pressure

and only a small amount of gas is flowing through the pipelines.

The sometimes explosive lifting of the float can cause damage to the flow meter, e.g.

glass breakage, deformation of the float stop, etc..

Remedial action:

- Increase the operating pressure or use devices with a lower pressure drop.

The operating pressure should be approx. 5 times higher than the pressure loss of the variable area flow meter. - Place shut-off devices behind the flow meter

- Use lightweight floats

- Use units with float damping.

The operating pressure of devices with dampers should be approx. 2 times higher than the pressure loss of the variable area flow meter.

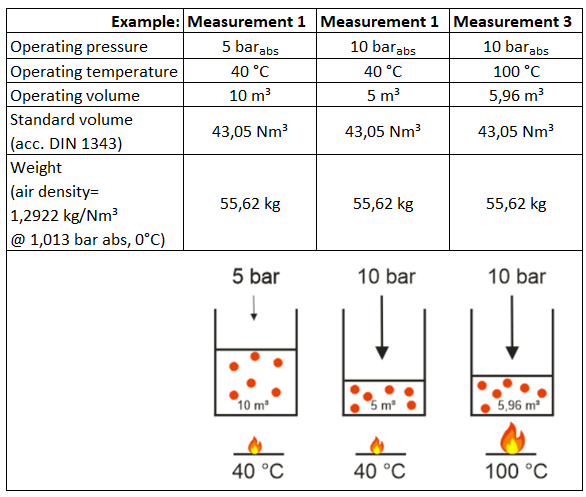

Differenz between standard conditions (acc. DIN 1343), standard conditions and operating conditions

Gases are normally compressible, i.e. when the pressure and/or temperature change,

they change their volume. The volume change can be calculated by the gas laws (Boyle-Mariotte law,

Gay-Lussac law, Charles law)

p x V / T = constant

(p=pressure in bar abs., T=temperature in K (=273 + °C), V=volume)

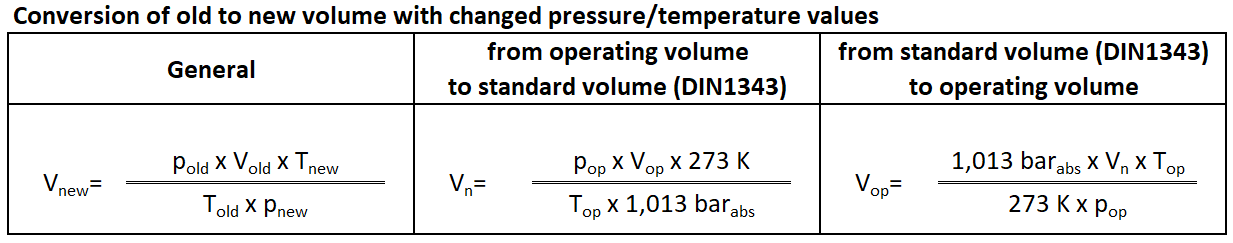

Told = Temperature at old volume (Kelvin), Tnew = Temperature at new volume (Kelvin), Top = Operating temperature (Kelvin)

Kelvin = 273 + °C

Vold= Volume at old pressure/temperature values, Vnew= Volume at new pressure/temperature values, Vn= Standard volume (DIN 1343)

The operating volume is the actual volume of a gas at operating pressure/operating temperature. An operating liter of gas at 20°C has a different number of gas molecules than an operating liter of gas at 50°C. In chem. reactions, mixing of gases etc. it is normally necessary to have a to mix a defined number of gas molecules.

In order to obtain comparable, defined values, the standard volumehas therefore been defined in DIN 1343.

The standard volume (acc. DIN 1343) is a volume that a gas would occupy at 1.013 bar absolute (=1013 hPa) and 0°C. It is identified by the letter "N" in front or subscript "n" (NL = standard liter, Nm³=norm-m³, ln etc.). A standard liter at 20°C contains the same number of molecules as a standard liter at 50°C. For the design of a variable area flowmeter, the specification of pressure and temperature are necessary.

In addition to operating volumes and standard volumes (according to DIN 1343), other standard volumes are used. These conditions are defined individually by different industries or even countries. In aviation, for example, 1.013 bar absolute (=1013 hPa) and 15°C is specified according to ISO 2533. Or also for different applications in Europe 1.013 bar absolute (=1013 hPa) and 20°C. The marking is made by a subscript "s" (ls= standard liter).

Over 90% of variable area flowmeters for gases have a standard volume scale.

The two terms standard volume (acc. DIN 1343), standard volume and operating volume are often confused in practice and thus lead to sometimes considerable measuring errors or an incorrect selection of a variable area flowmeter.